5-axis machining system with up to 30° axis orientation No extra rebuild between wet & dry processing necessary (only CORiTEC 250i touch) Tool runtime control/breakage control integrated cooling circuit for cooling lubricant HF spindle up to 60,000 rpm High-resolution and high-performance micro-step controllers and motors on all axes Air purge system and cooling nozzles for wet processing are integrated in the spindle holder Extraction system to extract the resulting particulate matter Automatic compressed air and coolant monitoring For processing of zirconium dioxide, PMMA, wax, plastics, and grindable block materials, prefabricated abutments Control software Remote DENTAL 3.0 Touchscreen operation with integrated Tablet-PC

544x650x612mm 95Kg

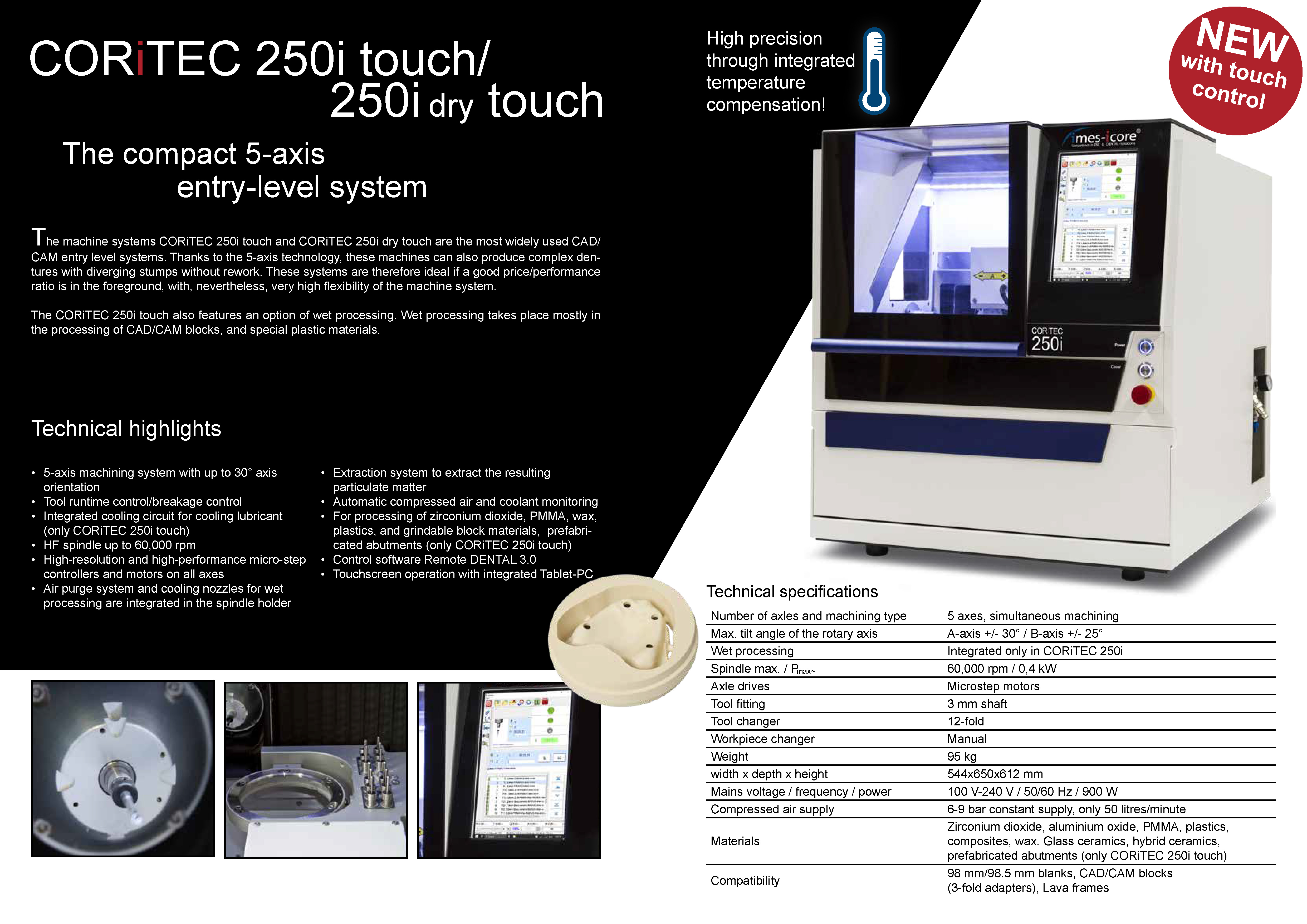

The CORITEC 250i and CORITEC 250i Dry & Wet are one of the most commonly used CAD / CAM systems for dental laboratories.

With 5 axes, this device is able to make complex dentures with divergent stumps without post-processing.

If you are looking for high performance / flexibility in your machine system but are still interested in value for money, the CORiTEC 250i touch is the perfect solution for you.

The CORiTEC 250i touch also has a wet machining option. Wet processing is mainly done during the processing of CAD / CAM blocks, special plastics, and even with a 7-piece automatic raw material filling system - CORiTEC 250i PRO Loader version.

Technical highlights:

5-axis machining system with up to 30° axis orientation

No extra rebuild between wet & dry processing necessary (only CORiTEC 250i touch)

Tool runtime control/breakage control integrated cooling circuit for cooling lubricant

HF spindle up to 60,000 rpm

High-resolution and high-performance micro-step controllers and motors on all axes

Air purge system and cooling nozzles for wet processing are integrated in the spindle holder

Extraction system to extract the resulting particulate matter

Automatic compressed air and coolant monitoring

For processing of zirconium dioxide, PMMA, wax, plastics, and grindable block materials, prefabricated

abutments

Control software Remote DENTAL 3.0

Touchscreen operation with integrated Tablet-PC

Tchnical scecifications:

| Number of axles and machining type | 5 axes, simultaneous machining |

| Max. tilt angle of the rotary axis | A-axis /- 30° / B-axis /- 25° |

| Wet processing | Integrated for the CORiTEC 250i |

| Spindle max. / Pmax~ | 60,000 rpm / 0,4 kW |

| Axle drives | Microstep motors |

| Tool fitting | 3 mm shaft |

| Tool changer | 12-fold |

| Workpiece changer | Manual |

| width x depth x height | 544x650x612 mm |

| Weight | 95 kg |

| Mains voltage / frequency / power | 100 V-240 V / 50/60 Hz / 900 W |

| Compressed air supply | 6-9 bar constant supply, only 50 litres/minute |

| Materials | Zirconium dioxide, aluminium oxide, PMMA, plastics, composites, wax. Glass ceramics, hybrid ceramics. prefabricated abutments (only CORiTEC 250i) |

| Compatibility | 98 mm/98.5 mm blanks, CAD/CAM blocks (3-fold adapters), Lava frames |